As data acquisition (DAQ) systems find increasingly widespread applications across various industries, their development is accelerating rapidly. From industrial automation and smart manufacturing to scientific research, environmental monitoring, and automotive electronics, DAQ systems have become an indispensable component of modern technology. Continuous technological advancements and growing market demands are constantly raising the requirements for DAQ system hardware components. In particular, the performance of the controller has become a critical factor influencing system stability and efficiency.

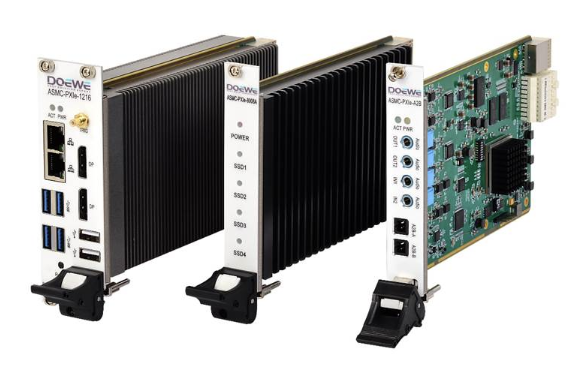

Figure 1 PXIe Controller Interface Diagram

Within a DAQ system, the controller acts as the core unit, responsible for the coordinated management of all modules. It ensures accurate data acquisition, rapid processing, and efficient transmission. The controller is far more than a simple data processing platform; it serves as the "central nervous system" or "brain" of the entire system's operation. A high-performance controller can effectively support parallel processing across multiple channels and the high-speed execution of complex tasks, enhancing the system's response speed and overall operational efficiency. Especially in application scenarios demanding real-time data processing or complex signal acquisition, the advantages of a high-performance controller become particularly pronounced, ensuring precision during data acquisition and overall system stability.

An excellent controller possesses powerful data processing capabilities, low latency, and high scalability. It not only supports the high-speed processing of large-scale data but can also be flexibly expanded in functionality based on application requirements, ensuring the system adapts to evolving technological needs. As application scenarios diversify, the controller's scalability becomes especially important. Particularly in test environments requiring frequent upgrades and maintenance, a flexible system architecture and modular design can significantly enhance the system's adaptability and long-term stability.

However, a poorly performing controller often becomes the bottleneck of a DAQ system. Low processing power, sluggish response, and poor stability directly impact the system's operational efficiency and the accuracy of data processing. Issues like controller latency, lack of multi-tasking capability, or even system crashes can lead to data loss, distorted analysis results, and ultimately affect the outcome of test projects. Especially in fields like industrial control and precision testing, inadequate controller performance can result in the loss of critical data, compromising the entire system's reliability and the accuracy of test results. Therefore, selecting a high-quality, high-performance controller is crucial for ensuring the smooth operation and efficient execution of a DAQ system.

Doewe Technologies' PXIe controller utilizes an advanced processor architecture, boasting powerful computing capabilities and high reliability, specifically designed for demanding test and data acquisition systems. Our ASMC_PXIe-1216 model features an Intel® Core™ i7-6820EQ processor, supporting quad-core/eight-thread parallel processing with a maximum processing speed of 2.8GHz and 8MB cache. Leveraging its superior computing power, this controller efficiently handles complex DAQ tasks, ensuring real-time and accurate data processing. It performs stably and efficiently even in highly challenging application scenarios.

Compared to other competing products on the market, Doewe Technologies' self-developed PXIe controller demonstrates significant technical advantages in several areas. Firstly, its intelligent bandwidth allocation function enables the controller to support up to 16GB internal bus bandwidth and up to 24GB external bus bandwidth. This design allows for more efficient management and allocation of data transmission resources, ensuring the system maintains excellent performance even under high loads.

Figure 2 Doewe Technologies PXIe Controller

Furthermore, the controller features adaptive configuration based on chassis mode, automatically selecting the optimal data transmission method. Whether it's a 2-path configuration (1 path x8GB/s, 1 path x16GB/s) or a 4-path configuration (4 paths x4GB/s), it provides flexible and efficient solutions tailored to different requirements, ensuring the system consistently meets application demands.

Regarding energy monitoring, Doewe Technologies' controller supports real-time power consumption and temperature reading. Users can monitor the device's operational status in real-time, ensuring stability and safety during high-load operation. This innovative feature not only aids in optimizing energy management but also extends the equipment's service life.

P2P (peer-to-peer) operation is another highlight of Doewe Technologies' controller. Different modules can transfer data directly between each other via the controller's P2P function, significantly improving data transfer efficiency, reducing system latency, and thereby ensuring DAQ tasks are completed efficiently and accurately.

Designed for high scalability, Doewe Technologies' controller comes standard with 16GB RAM and supports expansion up to 48GB, ensuring the system maintains exceptional performance even when handling large-scale data processing. For storage, the controller includes a standard 512GB SATA SSD. Users can also opt for higher-capacity storage configurations based on requirements, catering to high-load DAQ tasks and applications demanding significant storage space.

Our PXIe controller is compatible with both Windows 7 and Windows 10 operating systems. Equipped with multiple USB ports, network interfaces, and display ports, it offers high compatibility and flexibility, adapting to diverse system environments and application needs. The controller's modular design and multi-interface configuration make it widely applicable in fields such as electronic product testing, automotive electronics, aerospace, industrial automation, and scientific research, providing stable and reliable support. Additionally, Doewe Technologies' PXIe controller undergoes rigorous quality testing to ensure stable operation even in industrial environments with high temperatures and significant humidity fluctuations, as well as in precision laboratories, guaranteeing the efficient completion of data acquisition and processing tasks.

As a core component of a DAQ system, the performance and stability of the controller have a direct impact on the overall system efficiency. Doewe Technologies' PXIe controller, with its powerful computing capabilities, outstanding scalability, and high reliability, provides dependable support across various fields including test & measurement, industrial automation, and scientific research. Choosing a high-quality controller not only enhances the overall performance of the DAQ system but also safeguards the accuracy and security of the data acquisition process. Doewe Technologies remains committed to providing customers with efficient and stable controller products, empowering industries to realize an intelligent and automated future.

Figure 3 Doewe Technologies PXIe Chassis

Doewe Technologies is always committed to achieving innovative, unique, and reliable product solutions in the field of data acquisition. We deeply understand that these elements are the cornerstone for enterprises to establish themselves in market competition. For this reason, we derive innovative inspiration from customers' real application needs, rather than merely showcasing flashy product features. By continuously optimizing and enhancing data acquisition solutions, Doewe Technologies empowers partners to move towards an efficient and precise future. Welcome to choose Doewe Technologies and together embark on a new chapter in data acquisition. Contact Tel: +86-10-64327909.