1. Introduction

Digital radio is currently an essential feature for overseas automotive infotainment systems, with DAB (Digital Audio Broadcasting) being the most widespread. Since China no longer has actual DAB signal coverage, the entire industry chain is essentially absent domestically. This poses a significant challenge for engineers in China engaged in developing broadcast reception functions for automotive infotainment systems. How to conduct DAB function verification to ensure the stability and reliability of infotainment systems is a critical question every engineer involved in this task must address.

This article does not focus on specific functional points such as Linking, Announcement, Reconfiguration, SLS (Service Label and Slide), SPI (Service Provider Identification), EPG (Electronic Program Guide), or DLS (Dynamic Label Segment). Instead, it analyzes the methodology for DAB function verification from a higher dimension and briefly introduces industry-standard testing equipment that has established benchmark influence. Essentially, the testing industry is an intertwined system of testing standards, methodologies, and instruments—none can exist without the others. Any testing method must be supported by testing instruments to be implemented.

The testing methodology discussed here applies to both the R&D and QA stages. Readers can build testing platforms according to their actual needs.

2. R&D Verification Testing and Introduction to the RWC2010C

Every product undergoes the rigorous R&D phase, where engineers strive to meet product definition requirements. However, effective verification remains a crucial part of R&D. R&D testing differs from simple functional validation; it must be traceable to the root cause and generally requires: logical testing methods, well-founded testing principles, capable testing equipment, and repeatable test results.

To meet these requirements, a simple device with DAB RF signal generation capability is insufficient for R&D testing. For DAB R&D testing, the following basic requirements exist:

Precise, controllable, and adjustable RF signal parameters, generally including carrier frequency and power. Most standard devices offer this, differing only in precision, range, or channel count.

Physical layer verification must test not only ideal conditions but also the impact of fading and noise interference. This typically relies on channel simulators, which use specific models and parameters to ensure consistent test conditions.

Adjustable channel parameters, enabling instant modification of IDs or MODEs to verify the infotainment system’s rapid response.

Data service verification based on controllable instant modes, e.g., Announcement configurations must be flexibly modified and enabled/disabled, or multi-service validation must allow dynamic addition/removal of services to test system stability. Such tests are difficult to perform precisely with ordinary ETI (Ensemble Transport Interface) streams.

Complex scenario setup and repeatable verification. A typical example is Linking testing, especially Seamless Linking, which requires Service-level delay parameter settings to validate the infotainment system’s software processing capabilities. Given variations in real-world operator conditions, this verification is particularly complex. R&D testing solutions must gauge the system’s actual capabilities, supplemented by other methods introduced later.

Configuration, querying, and verification of underlying services, e.g., Service information, Start CU (Capacity Unit), and EPG core parameters, ensuring full controllability to validate protocol compliance.

The RWC2010C has gained recognition from numerous industry leaders for achieving these objectives.

This device supports AM/FM analog modulation and DAB/DRM/CDR digital modulation, with multi-channel FM output capability. Notably, its flexible baseband multiplexing function—an industry innovation—enables stream-level multiplex configuration for DAB/DRM/CDR, greatly enhancing test flexibility and efficiency to meet DAB infotainment R&D demands.

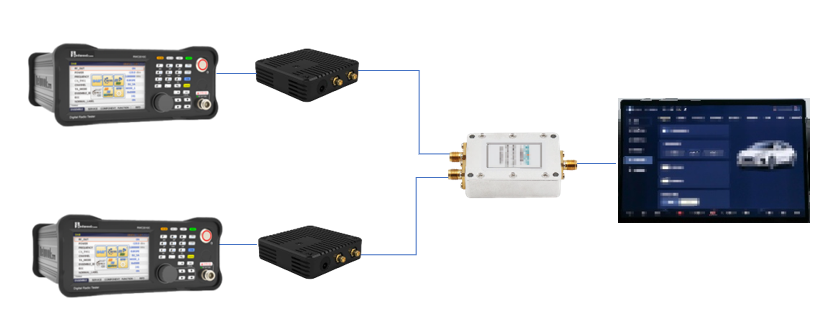

Using two sets of RWC2010C enables comprehensive Seamless Linking test scenarios, as shown in this typical system setup:

3. RF Environmental Signal Capture Verification and Introduction to RFCS

Unlike R&D testing, QA or vehicle validation focuses more on user experience (though R&D should theoretically also prioritize this). While capturing live DAB signals for testing is not a precise method theoretically, it holds practical value from a "practice yields truth" perspective. However, results obtained this way must be matched with theoretical analysis, as the parameters of captured signals and their suitability for verification require confirmation—blind testing wastes time.

The correct approach is:

Verify basic reception capabilities (e.g., scanning, selecting, switching stations, audio quality, and controls) by having the infotainment system directly receive operator DAB broadcasts (whether via direct reception or RF capture/replay devices).

Use operator signals to validate supported functions (e.g., Station Logo or Linking—functions operators rarely alter).

If operator program schedules or service timetables are obtainable, further validate functions like SLS.

For functions requiring operator actions (e.g., Announcement or DLS), operator activities must be clearly known. This is the most challenging aspect of field testing, as coinciding with operator actions is rare. Thus, instrument-based testing (via parameter configuration or playback of operator-provided ETI streams) is preferred.

Since China lacks DAB signals, "direct reception testing via driving" is impractical. Therefore, RF environmental signal capture is widely adopted. This method, established in the industry for years, aims to capture as many overseas real-world signals as possible for lab-based verification. When selecting capture equipment, consider:

High capture accuracy: IQ data should allow analysis via tools like MATLAB.

Minimal signal distortion during replay: e.g., if pre-capture MER (Modulation Error Ratio) is X, post-replay MER (Y) should closely match X.

Hot-swappable RAID-compatible storage: Data is invaluable; field recording requires ample, secure storage.

Integrated spectrum monitoring: Pre-capture spectrum scans confirm signal status.

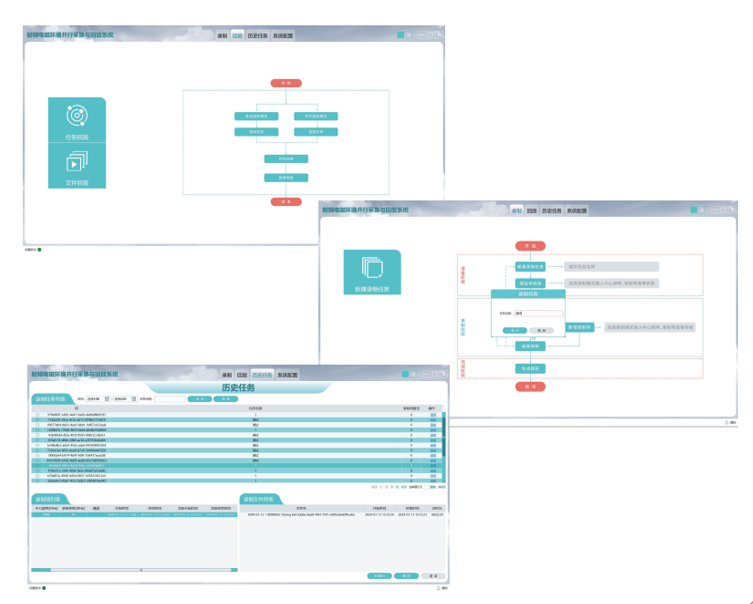

The RFCS (Radio Frequency Capture System) fulfills all four requirements. Its hardware is industry-proven, and its software offers English GUI and Chinese task management, scheduled recording, and multi-channel control.

Typical Interface of RFCS

Properly configured, RFCS can form multi-channel, wider-bandwidth test systems and synchronize with map/video data. Single-unit RFCS typically suffices for specific capture needs.

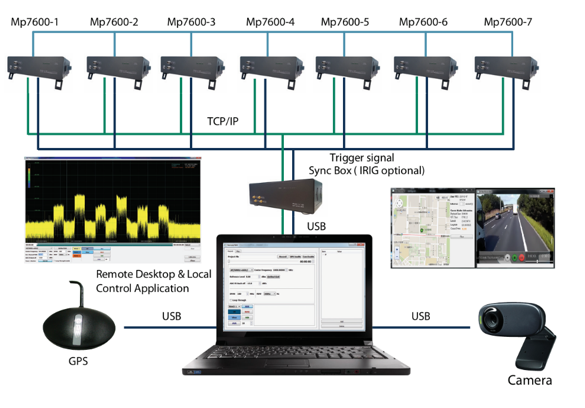

A multi-channel synchronous capture system is shown below:

4. ETI Stream Capture and Introduction to HEXYLON

Instrument vendors like RedwoodComm provide various ETI test streams, and the RWC2010C can edit streams—both features are industry-recognized. However, these streams are protocol-generated, not actual operator streams. A key industry pain point is obtaining operator DAB ETI streams, which could be replayed on standard instruments (e.g., RWC2010C) for broader infotainment verification.

ETI stream capture requires prior DAB RF performance analysis. Poor RF conditions can corrupt demodulated streams. Captured ETI streams should be archived with corresponding RF metrics to aid traceability.

HEXYLON elegantly solves this challenge with its portable design:

This portable device enables DAB RF performance analysis, as shown below:

After RF analysis, demodulated ETI streams can be recorded and replayed:

5. Combined Testing with the Three DAB Verification Tools

If the RWC2010C is the "Excalibur" and the RFCS the "Durendal" of DAB verification, HEXYLON is the "Art of War"—their interoperability enables diverse test cases. Key combined use cases include:

RWC2010C RF performance validation: HEXYLON tests DAB signals from standard instruments for link diagnostics.

Special stream capture and modulation: HEXYLON captures ETI streams for RWC2010C playback.

ETI material acquisition: HEXYLON demodulates RFCS-captured DAB signals into ETI streams; RWC2010C replays them at varied frequencies/power levels for infotainment validation.

RFCS replay troubleshooting: HEXYLON analyzes RF metrics for comparison.

RFCS content verification: HEXYLON demodulates signals into ETI streams; RWC2010C decodes the content.

Together, these core instruments unlock greater value.

6. Conclusion

DAB function verification for automotive infotainment is a hotspot and technical challenge in the automotive electronics industry. The "Three Essential Tools"—RWC2010C, RFCS, and HEXYLON—accelerate R&D, perfect DAB service functionalities, and enhance product competitiveness. Their combined use covers all aspects of DAB verification, providing engineers with rich test cases to rapidly locate and resolve issues.

If interested in this solution, contact Doewe Technologies at +86-10-64327909.