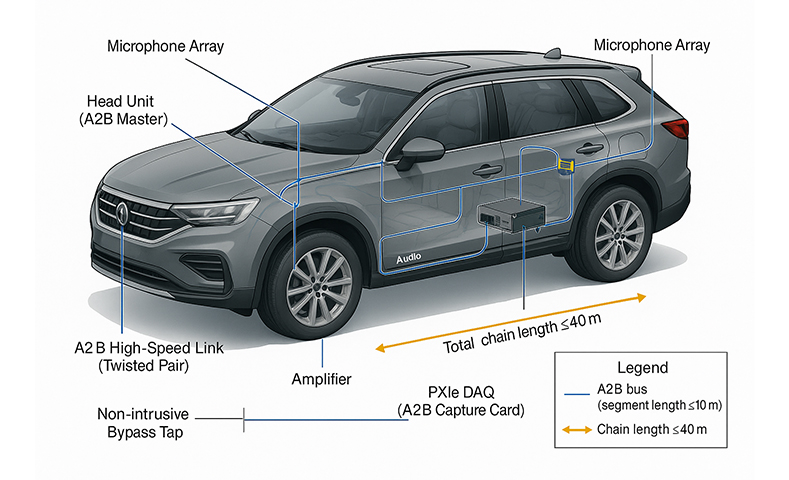

As in-cabin voice interaction, active noise cancellation (ANC), and zoned audio see deeper adoption, A²B (Automotive Audio Bus) in the vehicle takes on more time-sensitive, multi-channel audio transport tasks. A²B uses a single pair of unshielded twisted wires to synchronously carry audio and control, offering ~50 Mbps bandwidth, determinism with microsecond-level per-hop latency, and phase-aligned clocks across nodes. This makes it well-suited to multi-mic arrays and zoned playback scenarios, while imposing stricter requirements on link stability and timing consistency. In real vehicles, power fluctuations, EMC coupling, and harness layout can trigger frame errors, link reconstruction, or cumulative jitter that are hard to capture and reproduce on static benchtops alone. To address this, we build on a modular data-acquisition platform to provide a solution dedicated to A²B link lossless tap-in, long-duration logging, and online monitoring. By synchronously capturing protocol events and audio payloads, we form a closed loop of “discover—localize—verify—optimize.”

Our solution is built around PXIe and focuses on capture and analysis along the A²B link: we tap in bypass-mode without changing the original vehicle wiring or load relationships, obtain in real time the payloads on uplink/downlink channels across multiple nodes, and simultaneously log key protocol behaviors (e.g., frame errors, packet loss, and node online/reconnect timing). All data are processed under a unified time base, enabling linked analysis of spectrum, phase consistency, channel latency, and event timelines; with clip playback and A/B comparisons, engineers can validate the actual benefits of algorithmic or hardware fixes and produce traceable debug evidence. Because the A²B bus carries audio and control/I²C information over the same wire pair, we can present waveform and protocol-side information in an integrated way, significantly reducing the back-and-forth cost of troubleshooting.

This test system performs data acquisition and analysis on the A²B audio link: it covers uplink and downlink channels of master and slave nodes, supports parallel access to multiple nodes, and allows real-time monitoring. The acquisition card deframes, buffers, and time-aligns at the channel level the bus data, while the controller handles high-speed writing of high-bandwidth data streams, trigger-based recording, and visualization. Based on A²B’s frame structure and fixed frame rate (typically a 44.1/48 kHz frame time base) together with the bus’s high-bandwidth design (~50 Mbps), the system can continuously retain key clips without disturbing the link and output engineering-oriented KPIs (frame-error rate, number of reconnections, packet-loss peaks, etc.) to quantify link stability and audio consistency.

In this test system, A²B audio signals are losslessly tapped and deframed by the A²B acquisition card within the data-acquisition system. The controller timestamps audio and protocol events uniformly and processes them on the same time axis; the display module presents channel levels, spectra, and clip export in real time for easy review and comparison. The system is powered via a cigarette-lighter socket, and with wide-voltage input and power-loss buffering it ensures data integrity and continuity under start–stop conditions and over long-duration recording.

This test solution offers multiple technical advantages, as follows:

1. Self-developed core products: self-developed PXIe controller, solid-state storage module, and data-acquisition chassis; deep integration of drivers, GUI, and protocol parsing; high software–hardware consistency to reduce compatibility and maintenance costs.

2. Multi-node audio capture with a single device: a single unit supports up to 10 nodes and 32-channel A²B audio parallel capture with channel-level synchronization, and displays alongside protocol events on the same screen to quickly pinpoint root causes.

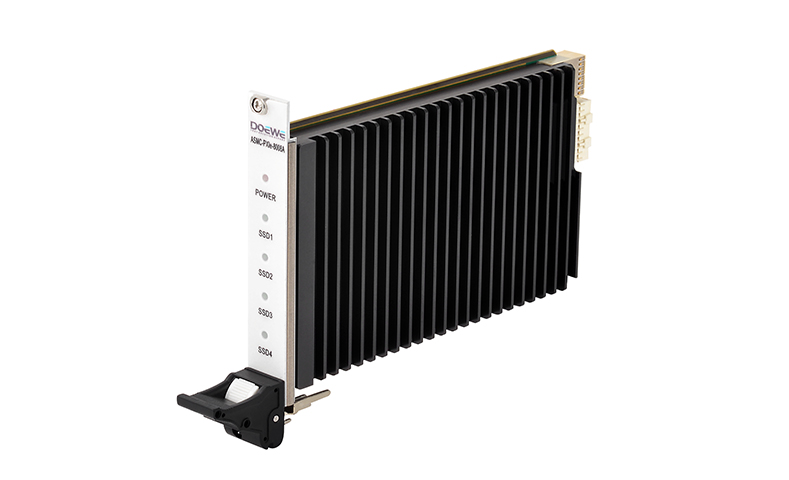

3. Integrated storage:16-TB-class PXIe solid-state storage mounted directly to the chassis with sustained write bandwidth >6 GB/s, meeting requirements for long, high-bandwidth recording and zero-frame-drop retention.

4. System integration and reliability: acquisition card, controller, and storage are highly integrated in a PXIe anti-shock enclosure; optional connectors and cable retention reduce the risk of loosening due to bumps, suitable for long road tests and durability scenarios.

5. High-performance data processing: the controller provides a high-throughput, low-latency data pipeline and supports multi-format report export to improve cross-team collaboration efficiency.

The core test equipment of this solution are: the PXIe controller, the storage card, and the A2B acquisition card. The specific equipment are described below:

A²B acquisition card:

The ASMC-PXIe-A²B uses 32-bit ΔΣ ADC/DAC with sampling rates covering 48/96/192/384/768 kHz, spanning from voice to high-bandwidth scenarios; at 48 kHz it achieves >110 dB SNR and THD+N < –110 dB. An onboard A²B transceiver (AD2428) supports up to 11 nodes (1 master + 10 slaves) and 32 uplink/32 downlink channels, and a maximum bus length of about 40 m, fitting a vehicle daisy-chain topology. The card provides 2 Vrms analog I/O and 3.5 mm TRS compatible single-ended/differential inputs, and it integrates an IEPE constant-current source and supports TEDS identification to facilitate cooperation with sensors/fixtures. For R&D bring-up and compatibility verification, it can capture bus waveforms as well as support node-level testing and signal injection to quickly locate link and audio-consistency issues.

The ASMC-PXIe-1216 adopts an Intel® Core™ i7-6820EQ (2.8 GHz, 4 cores/8 threads) in a 3U dual-slot form factor, providing 16 GB memory (expandable), a 512 GB SSD, 2× Gigabit Ethernet, 4× USB 3.0/2× USB 2.0, and DisplayPort (up to 3840×2160@60 Hz). The controller integrates PCIe switching and smart bandwidth allocation, and can adaptively switch between 2-lane (1×x8 + 1×x16) and 4-lane (4×x4) modes according to the chassis LINK status; it supports P2P direct connection to reduce data loopback latency and CPU load, and offers real-time power and temperature monitoring to ensure long-term stable operation. SMB trigger/backplane trigger and bus bandwidth up to 16 GB/s internal and 24 GB/s external provide headroom for high-speed acquisition and playback.

The ASMC-PXIe-8016 is a 3U single-slot solid-state storage module with up to 16 TB capacity and a PCIe x8 interface; typical sequential read/write reach 6.67/6.53 GB/s, meeting the needs of long, high-bandwidth recording and zero-frame-drop retention. The card integrates slot identification for positioning and data management in multi-card deployments; it supports energy (power) monitoring for operating-state and reliability evaluation; the B series adds P2P pass-through, enabling low-latency inter-module data interconnect under the same switch chip. Combined with the controller’s bandwidth and trigger system, a highly reliable data path from acquisition to retention can be built.

This test solution follows the principle of “do not disturb the original vehicle, restore the real link,” building a closed-loop process from issue capture and evidence solidification to reproduction and verification. Through non-intrusive bypassing, synchronous capture of protocol events and audio payloads, and long-duration high-speed storage with replayable analysis, the system can stably achieve multi-node, long-duration, reviewable A²B evaluation in both bench and in-vehicle scenarios, markedly improving localization efficiency and quantifying optimization gains. The solution has clear advantages in protocol-integrity assessment, evidence-chain creation, and team collaboration, providing continuous support for algorithm calibration, hardware iteration, and mass-production quality inspection.

Doewe Technology is committed to delivering innovative, distinctive, and reliable product solutions in the field of data acquisition. We understand that these elements are the bedrock for enterprises to stand out in market competition. For this reason, our innovation draws inspiration from customers’ real application needs, rather than showcasing flashy but impractical product features. By continuously optimizing and enhancing data-acquisition solutions, Doewe Technology helps partners move toward an efficient and precise future. We welcome you to choose Doewe Technology and open a new chapter of data acquisition together.