Data acquisition (DAQ) systems play a critical role in modern industry, scientific research, and engineering. Their primary task is to collect, process, store, and analyze various signal data, providing users with reliable decision-making support. A DAQ system consists of DAQ cards, a chassis, a host computer, and a display screen, all working in synergy to achieve efficient data processing and presentation. These components combine uniquely across different types of DAQ systems. This article explores the main components of DAQ systems and their application characteristics across various system types.

The core component of a DAQ system is the DAQ card, responsible for acquiring and processing external signals. Through analog-to-digital converters (ADCs) and digital-to-analog converters (DACs), DAQ cards convert signals from analog to digital or vice versa, while supporting multiple input/output interfaces. Typical functions include signal conditioning, sampling, amplification, and filtering, widely used in industrial automation, scientific experiments, and environmental monitoring. The choice of DAQ card often determines the overall system performance and is thus a key consideration in DAQ system design.

Figure 1: DAQ Card Schematic

The host computer serves as the data processing center of the DAQ system. It receives data acquired by the DAQ cards and performs analysis, storage, and visualization. Depending on application needs, the host can be an embedded computer, an industrial PC (IPC), or a standard PC. Key functions include controlling DAQ card operations, running analysis algorithms, and storing acquired data, making it suitable for complex tests with large data volumes. For example, in acoustic measurements, the host can store multi-channel data while simultaneously performing spectral analysis to support engineering decisions. Modern hosts are often equipped with powerful computing capabilities and data transfer interfaces (e.g., Ethernet, USB) to ensure efficiency and real-time performance.

The display screen and chassis together form the critical display and mounting components of the DAQ system. The screen displays real-time data and system status for user monitoring and operation, while the chassis protects and houses the DAQ cards while providing necessary interface support. Technicians can monitor experimental data in real-time via the screen, and the chassis ensures operational stability and anti-interference capability. In many high-end DAQ systems, the screen also supports touch operation, enabling rapid configuration adjustments.

Based on integration level and structural design, DAQ systems can be classified into Fully Integrated Systems, All-in-One Systems, Controller-Integrated Systems, Modular Systems, and Highly Integrated Card Systems. Each type has unique functional and application characteristics.

Fully Integrated DAQ Systems combine the host, chassis, display, and DAQ cards into a compact, single device. Featuring a built-in display (no external monitor required) and excellent anti-interference capability, they are ideal for field testing and long-term fixed monitoring. Often equipped with a built-in battery, they support extended standalone operation, enhancing suitability for remote or harsh environments. For example, in bridge health monitoring, these systems can record vibrations and displacements 24/7. However, non-replaceable cards limit functional flexibility and upgrades, leading to higher maintenance and expansion costs.

All-in-One DAQ Systems integrate the host and chassis into a single unit with a built-in display. The host handles data acquisition and processing, while users can install different DAQ cards into the chassis based on needs. Real-time data is displayed via the built-in screen. These systems offer strong expandability and portability, suitable for long-term monitoring and multi-location signal acquisition. Cards can be swapped as tasks change, with high-end models supporting hot-swappable cards for enhanced flexibility. Downsides include limited card capacity due to space occupied by the screen/host and relatively high overall cost.

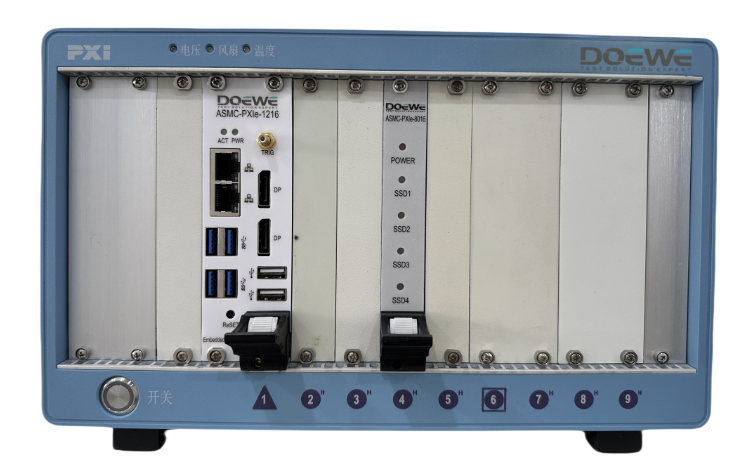

Controller-Integrated DAQ Systems (Chassis-Based) feature a built-in controller for autonomous operation without an external host. Users only need to connect a display and DAQ cards for data acquisition and preliminary processing. A single chassis can house multiple cards, supporting high-channel-count acquisition for large data volumes. However, their size and weight make them unsuitable for relocation after installation, best for long-term fixed tasks. The controller supports multiple interfaces (e.g., RS485, CAN bus) and provides computational power for preprocessing and protocol conversion. Some systems also support remote management/monitoring, boosting efficiency in complex industrial environments.

Figure 2 Schematic Diagram of Chassis-Integrated Data Acquisition System

Modular DAQ Systems comprise separate hosts, chassis, displays, and DAQ card modules. They offer high flexibility and low-cost advantages, facilitating setup and debugging. Limited card capacity and complex architecture make them more suitable for education/training or general industrial testing with fewer channels or less demanding environments. Their applicability diminishes for high-channel-count or harsh-environment scenarios.

Highly Integrated DAQ Cards feature built-in front-end designs and connect directly to computers via interfaces like USB, requiring no additional devices. Their simple structure suits portable testing and rapid verification. Researchers can connect them to laptops for quick signal acquisition and analysis. Emphasizing plug-and-play functionality with user-friendly interfaces, they deploy rapidly for simple tests. However, their basic data acquisition capabilities are insufficient for highly complex testing needs.

In practice, selecting the right DAQ system requires balancing factors such as signal types/volumes, operating environment, scalability, and budget. For instance, industrial sites demand high-temperature/waterproof devices, while labs prioritize precision and flexibility. The diversity of DAQ systems enables them to meet varied needs—from laboratories to industrial sites. From highly integrated all-in-one units to flexible modular designs, each architecture serves specific scenarios. Choosing appropriately enhances testing efficiency and ensures data accuracy and reliability, providing robust support to users.

Doewe Technologies is committed to delivering innovative, unique, and reliable product solutions in the field of data acquisition. We understand these elements are the cornerstone of competitiveness. Thus, our innovation is inspired by genuine customer needs, not merely showcasing flashy features. By continuously optimizing DAQ solutions, Doewe empowers partners to achieve efficient and precise outcomes. Choose Doewe Technologies to jointly open a new chapter in data acquisition.