1. Introduction to DAQ Systems

A Data Acquisition (DAQ) system is an integrated system that combines data acquisition technology, computer technology, sensor technology, and signal processing technology. It primarily uses sensors to collect signal data from target objects, processes and filters the data through analytical mechanisms, and stores it. DAQ systems can capture various types of data—both analog and digital—in real time and with high accuracy, converting it into formats that computers or other devices can process, transmit, or display.

The workflow of a DAQ system typically includes the following steps:

- Signal Acquisition: Sensors convert physical quantities (e.g., temperature, pressure) into electrical signals.

- Signal Conditioning: Amplification, filtering, or analog-to-digital conversion prepares signals for computer processing.

- Data Analysis & Visualization: Software analyzes, processes, and displays data as reports, charts, or graphs.

- Data Storage: Processed data is stored for further analysis.

1.1 Components of a DAQ System

Data acquisition systems typically consist of signal acquisition and processing modules, sensors, computers, data processing and analysis software, etc. The signal acquisition and processing module is responsible for receiving signals from sensors and preprocessing them (e.g., conditioning, filtering, conversion) into formats analyzable by software; sensors are used to monitor and sense various physical quantities (such as temperature, pressure, flow, etc.) and convert them into electrical or other signals; the computer serves as the carrier for data processing and analysis software and can also act as a data storage tool; data processing and analysis software is responsible for analyzing, processing, and displaying data, presenting it intuitively in the form of reports or charts.

1.2 Classification of Data Acquisition Systems

Data acquisition systems can be divided according to different classification criteria:

1)According to Deployment Mode:

Centralized Data Acquisition System: Data acquisition tasks are undertaken by a central node, and other nodes send data to this central node. Suitable for scenarios with small data volume and few nodes.

Distributed Data Acquisition System: Data acquisition tasks are distributed across multiple nodes, which independently collect and may preliminarily process data. Suitable for scenarios with large data volume, many nodes, and needs for parallel processing.

2)According to Collected Data Type:

Structured Data Acquisition System: Primarily collects structured data stored in relational databases. Data formats are fixed, easy to process and analyze.

Unstructured Data Acquisition System: Collects unstructured data such as text, images, audio, and video. Data formats are diverse, and processing/analysis is relatively complex.

3)According to Application Scenario:

Industrial Data Acquisition System: Applied in industrial automation, intelligent manufacturing, etc., to collect various parameters on production lines. Emphasizes real-time performance, reliability, and stability.

Environmental Monitoring Data Acquisition System: Applied in environmental protection, meteorological monitoring, etc., to collect environmental parameters (e.g., temperature, humidity, air quality, etc.). Emphasizes long-term operation, data accuracy, and reliability.

Smart IoT Data Acquisition System: Applied in smart homes, smart cities, etc., to collect status and data of various smart devices. Emphasizes interconnection, data sharing, and intelligent processing.

1.3 Application Fields of Data Acquisition Systems

Industrial Field: Used for production line monitoring and automated control to improve production efficiency.

Environmental Protection and Monitoring Field: Used to monitor air quality, water quality, noise, and other indicators, providing decision support for governments and relevant agencies.

Agricultural Field: Used to monitor environmental factors such as soil moisture, temperature, and light to help farmers optimize irrigation, fertilization, and planting schemes.

Medical Field: Used to monitor patients' physiological indicators (such as heart rate, blood pressure, body temperature, etc.), providing timely medical information for healthcare personnel.

Traffic Management Field: Used to monitor traffic flow, vehicle speed, road conditions, etc., optimize traffic signals, and improve road traffic efficiency.

2. Typical Applications

Environmental Monitoring: Air Quality Monitoring Network

Application Scenario:

Air quality monitoring stations are an important part of modern urban environmental protection. Through real-time monitoring of pollutants such as PM2.5, PM10, sulfur dioxide, nitrogen dioxide, and ozone in the atmosphere, they provide a scientific basis for government decision-making and public health warnings.

The data acquisition system captures environmental parameters in real time through a sensor network. The data collector converts these analog signals into digital signals and uploads the data to the server according to preset time intervals or trigger conditions. The server uses big data analysis and machine learning algorithms to process massive data, identify pollution trends, and predict air quality changes.

Equipment Used:

Laser scattering particle sensors: Used to detect the concentration of particles such as PM2.5 and PM10.

Electrochemical sensors: Used to monitor the concentration of gaseous pollutants such as sulfur dioxide, nitrogen dioxide, and ozone.

Weather stations: Including wind speed and direction sensors, temperature and humidity sensors, etc., for collecting meteorological data.

Data collectors: Integrate multi-channel analog/digital inputs, responsible for collecting sensor data and transmitting it to the data center via 4G/5G networks.

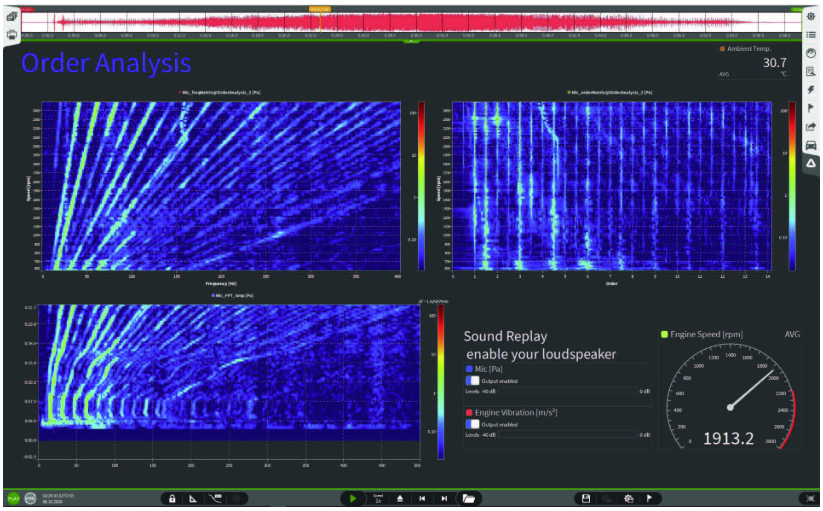

2. Industrial Measurement: Order Analysis

Application Scenario:

Order analysis is a tool that correlates the frequency spectrum and time history with the RPM (revolutions per minute) of rotating components to reveal the mechanisms of vibration and noise. In rotating and reciprocating machinery, changes in load and defects in moving components can cause vibrations, which in turn radiate noise. The form of vibration is related to the structural characteristics of mechanical movement and stationary components, and order analysis can link these vibration and noise signals to the rotational speed of rotating components, thereby revealing their internal mechanisms.

During the start-up and shutdown phases of rotating machinery, failures or hidden defects are likely to occur. Therefore, data acquisition equipment can be used to collect vibration or sound signals of rotating machinery. Using the order analysis function of the data acquisition equipment, the operating conditions of the equipment under different rotational speed conditions can be analyzed by tracking the rotational speed and frequency.

The rotational speed curve of the equipment can be calculated based on the collected pulse signals. The rotational speed curve describes the change of the equipment's rotational speed over time. Based on the rotational speed curve, the angle change curve of the equipment can be further calculated, which describes the change of the equipment's rotation angle over time, etc.

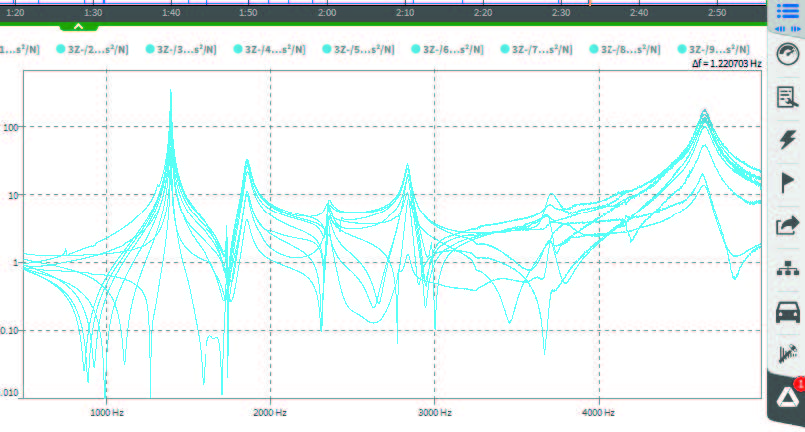

3. Modal Testing: Modal Analysis

Application Scenario:

Modal testing is a key engineering testing technology for in-depth exploration of the dynamic characteristics of structures, focusing on analyzing core parameters such as the natural frequency, modal damping, and modal shape of structures. These parameters are of great importance in structural dynamic design, fault diagnosis, and damage identification.

A controllable excitation signal (which can be sound waves, mechanical impact, electromagnetic excitation, etc.) is applied to the measured structure through an excitation device to make it vibrate. Sensors (such as accelerometers, displacement meters, etc.) are then used to capture the vibration response of the structure and measure the vibration displacement, velocity, or acceleration of the structure. Finally, the data acquisition equipment collects and records the signals from the sensors. After processing and analyzing the data, a modal model can be established, which can be used to predict the dynamic response of the physical structure under different conditions.

4. Smart Agriculture: Farmland Environment Monitoring System

Application Scenario:

The farmland environment monitoring system is used to monitor environmental parameters such as soil moisture, temperature, and light intensity in farmland in real time, providing data support for precision agriculture.

Various sensors in the farmland collect environmental parameters in real time. The data collector converts these data into digital signals and sends them to the data center through a wireless transmission module. The data center processes and analyzes the received data to provide farmers with precise agricultural management suggestions.

Equipment Used:

Soil moisture sensors: Used to measure the water content in the soil.

Temperature sensors: Measure the temperature of the farmland environment and soil.

Light intensity sensors: Monitor the light conditions in the farmland.

Data collectors and wireless transmission modules: Collect sensor data and transmit it to the data center via wireless networks.

5. Aerospace: Wind Tunnel Testing

Wind tunnel testing involves placing models of aircraft or other objects in a wind tunnel, artificially creating airflow to flow through the models, simulating various complex flight states in the air, and obtaining test data. In the aerodynamic testing of aircraft as a whole or its components, the wind flow parameters in the wind tunnel are first set to simulate the real atmospheric environment, such as wind speed, wind direction, temperature, humidity, etc. Then, data acquisition equipment is used to install a large number of sensors on the DUT to record and analyze various data generated during the experiment.

Data acquisition equipment plays a crucial role in wind tunnel experiments. It can not only record experimental data in real time and accurately but also provide high-precision and high-sensitivity measurement capabilities to ensure the accuracy and reliability of experimental results.

Due to the large number of sensors, high dynamic range of signals, and high sampling rate in wind tunnel testing, the simultaneous acquisition and storage of all signals are extremely important during the testing process. The high-precision sampling rate and multi-channel simultaneous acquisition of data acquisition equipment are particularly important. In addition, it is necessary to ensure that the equipment can be reliably used in harsh environments. Therefore, wind tunnel experiments put forward high requirements for the functionality and stability of data acquisition equipment.

6. Smart City: Traffic Flow Monitoring and Intelligent Scheduling

Application Scenario:

In smart cities, data acquisition systems are used to monitor traffic parameters such as traffic flow and vehicle speed, providing data support for intelligent traffic management and scheduling.

Data acquisition equipment captures video images of traffic scenes through video surveillance cameras. Image recognition and processing algorithms process and analyze the video images to extract traffic parameters. These parameters are collected by the data acquisition equipment and transmitted to the data center. The data center processes and analyzes these data to provide decision support for intelligent traffic management and scheduling.

Equipment Used:

Video surveillance cameras: Used to capture video images of traffic scenes.

Image recognition and processing algorithms: Extract traffic parameters (such as the number of vehicles, vehicle speed, etc.) from video images.

Data collection and transmission equipment: Collect processed data and transmit it to the data center via wireless networks.

With deep professional accumulation and sincere service in data acquisition systems, our company provides customers with excellent solutions and high-performance data acquisition instruments, sincerely helping customers overcome testing challenges. Relying on strong technical capabilities and rich business experience, we invite all sectors to inquire and seek common development.

Beijing Doewe Technologies Co., Ltd. owns the independent brand "Doewe Instruments," focusing on the research, development, production, and sales of electronic testing and measurement instruments/test systems. After years of development, the company's business scope covers multiple fields, with several business directions established: Radio/AV Division, Transportation Division, University & Research Institute Division, and Consumer Electronics Division. Our company unremittingly pursues innovation in testing and measurement technologies, dedicated to technology development, application software services, and research on testing and measurement solutions. To this end, we have established the "Doewe Technologies Center" in Beijing and the "Qingdao Technical Service Center" in Qingdao. Relying on the Beijing headquarters and related technology centers, the company has gradually established a nationwide service and marketing network, including Northeast Office, East China Office, Southwest Office, and South China Office, which can provide you with timely pre-sales and after-sales services.

Tel: 010-64327909

Website: https://www.doewe.com

Email: info@doewe.com

Address: Room 1821, Building 2, Soubao Business Center, 16 South Third Ring West Road, Fengtai District, Beijing