1、Solution Overview

This solution focuses on the comprehensive performance of electronic devices or other test objects in terms of temperature and power consumption under both regular and various extreme operating conditions. It provides an integrated capability of "data acquisition + intelligent analysis + environmental adaptability evaluation" for products such as set-top boxes, routers, industrial PCs, and more. The system is based on a PXIe modular platform, integrating temperature acquisition cards, power analysis cards, and control-storage units within the same chassis, with an external programmable environmental chamber for collaborative operation of temperature-power testing and environmental stress loading. The solution supports synchronous recording of device casing/environment temperature and power consumption curves under conditions set between −40°C to +150°C and 10%–98% RH, precisely revealing the device's heat dissipation performance and energy consumption peaks.

The system consists of both hardware and software components. The hardware part includes the temperature acquisition card, power acquisition card, embedded controller, and high-speed storage card, all housed in the modular PXIe chassis. The temperature acquisition card is responsible for high-speed, high-precision sampling from multiple thermocouples; the power acquisition card measures voltage and current synchronously and calculates power in real-time; the embedded controller coordinates data flow via a high-speed backplane bus and writes to large-capacity storage in milliseconds, ensuring lossless preservation of raw waveforms. The PXIe chassis provides high-bandwidth backplanes, vibration-resistant mechanical structures, and compact rails. It can be customized in size and installation methods based on site requirements, and supports plug-and-play insertion of additional PXIe modules for rapid expansion of more testing channels or functional modules.

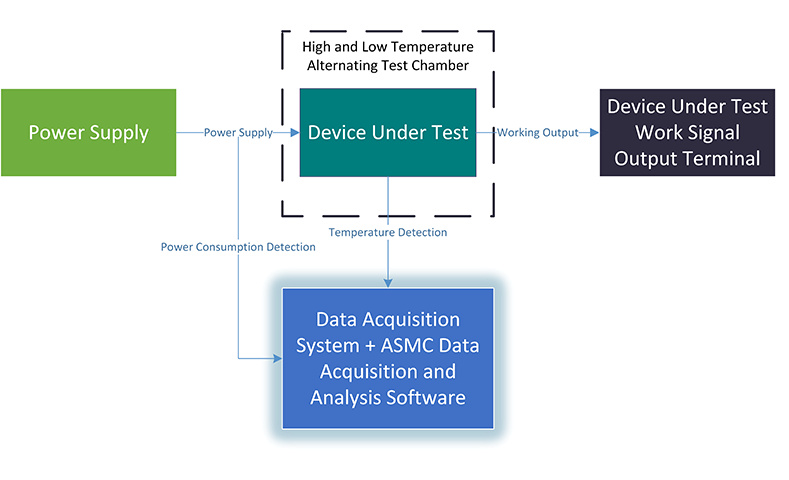

The ASMC Control and Analysis Software centrally manages all PXIe modules except the environmental chamber, providing real-time display and synchronous storage of multi-channel temperature, voltage, and current data, with one-click batch export capabilities. During temperature testing, the system continuously plots 24-hour curves, supporting independent/combined views, highlighting or hiding any channel, and instant annotation of the highest temperature and ΔT. During power consumption testing, the software calculates instantaneous power based on synchronized voltage and current, generating ≥ 2-minute curves and dynamically displaying average, real-time, maximum, and minimum values. Channel-level synchronization throughout ensures consistency in temperature rise and power consumption data, with raw data and analysis reports available for export at any time. The overall structure of the testing system is shown below:

2、Specific Testing Plan

2.1 Testing System Principle

Through the collaboration of hardware and software, this platform enables the synchronized measurement and analysis of key parameters such as temperature changes and power consumption of the device under test (DUT) during the calibration process. The testing process begins by placing the DUT into a programmable high and low temperature alternating test chamber. The test chamber applies environmental stress to the device based on the preset temperature and humidity curves, simulating real-world operating conditions. An external programmable power supply provides continuous power to the DUT, and if necessary, an output signal reception module can be connected to real-time assess the device's functional status under extreme temperatures.

Temperature measurements are made using multi-channel thermocouples: the probes are introduced into the chamber via a temperature acquisition card, monitoring the DUT’s casing or hotspots, with a dedicated environmental temperature channel. The number of channels can be configured freely according to the project requirements.

Power consumption testing is directly integrated into the power supply circuit by the power acquisition card, which synchronously collects voltage and current data and instantly calculates power. All acquisition cards are installed in the PXIe chassis, and the ASMC control and analysis software centrally manages the hardware resources. It provides real-time visualization of temperature rise and power curves, automatically saves raw data, and generates test reports.

Thanks to the modular card design and programmable environmental chamber, the system can be easily expanded with additional test channels or higher stress levels to meet future iteration needs.

2.2 Introduction to ASMC Data Acquisition and Testing Analysis Software

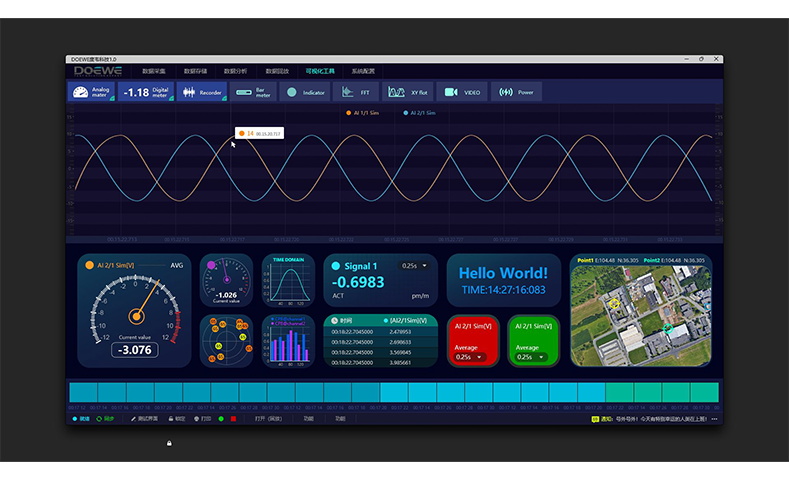

ASMC Data Acquisition and Testing Analysis Software is a comprehensive and efficient testing tool designed specifically for high-precision data acquisition and real-time analysis. The software provides real-time waveform and spectrum display functions, allowing users to simultaneously plot time-domain curves for each temperature, voltage, and current channel, with quick switching to spectrum graphs to help users promptly identify transient anomalies or noise peaks. With a unified hardware clock, ASMC enables channel-level synchronized acquisition, ensuring that data collection across all channels is strictly synchronized, providing precise support for subsequent algorithm calculations and comparative analysis.

To meet the needs of long-term steady-state or cyclic stress testing, the software automatically generates 24-hour temperature curves, with each temperature measurement channel continuously plotting temperature-time curves for no less than 24 hours, fully recording the thermal history. Additionally, ASMC features real-time power consumption curves and statistical metrics, enabling real-time calculation of power based on synchronized voltage and current data, and generating at least 2-minute power curves displaying key data such as average, real-time, maximum, and minimum values.

During testing, ASMC continuously calculates ΔT in real-time, showing the highest temperature in the current window and computing the maximum temperature rise ΔT in relation to the environmental temperature channel, providing a clear visual representation of thermal efficiency. The automated module control greatly enhances operational convenience, allowing users to start, pause, or stop all acquisition modules (except for the environmental chamber) with a single click from the same interface, avoiding frequent software switching and improving operational efficiency.

To meet diverse analytical needs, the software also supports individual/combined view functions, enabling users to zoom in and independently view the curve of any channel, or overlay and compare curves from multiple channels, making it easy to observe trends across different measurement points or test stages. The highlight/hide channel function allows users to highlight key curves with a single click, while unselected channels automatically fade or hide, keeping the interface clean and focused.

ASMC supports local data storage, ensuring the integrity of data during long-term testing, and supports multiple export formats. Users can export test results to commonly used file formats with a single click, facilitating subsequent offline analysis or direct insertion into reports. With its powerful features and efficient user interface, the software provides comprehensive and reliable data acquisition and analysis support for testers.

2.3 Core Parameters of the Testing System

- Number of Temperature Acquisition Channels: 8 channels for temperature + 1 channel for CJC

- Temperature Resolution: 24 bit

- Temperature Sampling Rate: Up to 256 S/s (synchronized across all channels)

- Supported Thermocouples: J, K, T, E, N, B, R, S

- Temperature Measurement Range: −200°C to +1300°C (depending on thermocouple type)

- Temperature Measurement Accuracy: ±0.1°C (typical)

- Number of Power Consumption Acquisition Channels: 8 channels

- Power Consumption Resolution: 12 bit

- Power Consumption Sampling Rate: Up to 500 kS/s

- Voltage Range: 0 V to 10 V

- Power Measurement Accuracy: ±0.5% FS (typical)

- System CPU: Intel Core™ i7-6820EQ, 2.8 GHz (Boost 3.5 GHz)

- System Memory: Default 16 GB (expandable up to 32 GB)

- Storage Capacity: SSD up to 16 TB

- Sustained Read Speed: 6.67 GB/s

- Sustained Write Speed: 6.53 GB/s

3、Advantages and Features of the Solution

3.1 Single-Unit Multi-Node Temperature-Power Synchronous Acquisition: A single PXIe platform can simultaneously acquire multiple temperature probes and multi-channel voltage/current signals with millisecond-level time alignment, avoiding synchronization errors and complex wiring associated with distributed instruments.

3.2 Integrated Storage and Multi-Source Sensor Integration: The 16 TB storage card is directly installed into the chassis, enabling long-term, high-frequency data to be written at once. Voltage, current, temperature, and other signals are unified through the corresponding PXIe dedicated acquisition cards, simplifying wiring and improving synchronization.

3.3 High Integration and Environmental Reliability: The temperature acquisition card, power acquisition card, controller, and storage card are all installed within the PXIe chassis, with a vibration-resistant structure and industrial-grade backplane that eliminate the risk of loose connections, ensuring long-term stable operation in high-temperature and high-vibration environments ranging from -40°C to +70°C.

3.4 High-Performance Data Processing: The embedded controller is equipped with a multi-core CPU and FPGA acceleration logic to calculate ΔT, instantaneous power, and statistical parameters in real-time. Its processing performance surpasses that of conventional rugged tablets or laptops, ensuring data timeliness and accuracy.

3.5 Flexible Customization and Expansion: The modular card design supports the addition of high-speed sampling cards, CAN/LVDS bus cards, and more, based on demand. The software offers an open API for secondary development of scripts and algorithms, easily adapting to various scenarios such as R&D validation, production line sampling, or after-sales diagnostics.

3.6 Real-Time Visualization and Automatic Reporting: The ASMC software synchronously displays temperature rise and power consumption curves, allows instant highlighting of key channels during testing, and automatically generates test reports, significantly shortening the "testing-analysis-decision" feedback loop.

3.7 Core Products Developed In-House: Core devices such as the storage card, controller, and data acquisition chassis are all independently developed by Doewe Technologies, ensuring overall product compatibility and consistency. After-sales maintenance is more convenient, providing more stable and reliable technical support.

4、Core Hardware Product Introduction

4.1 Temperature/Power Consumption Acquisition Card Core Parameters

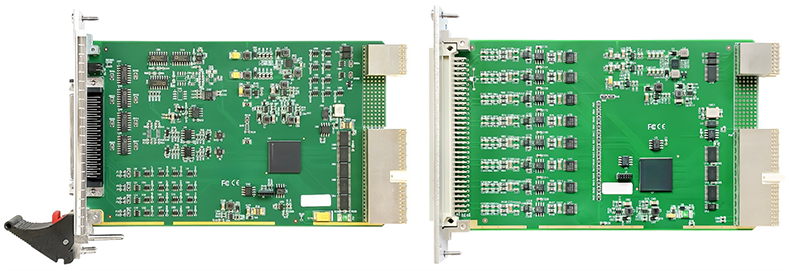

Doewe Technologies' power consumption acquisition card and temperature acquisition card provide high-precision acquisition solutions for power testing and temperature monitoring, respectively. The power consumption acquisition card focuses on the precise measurement of voltage and power, supporting multi-channel voltage acquisition, efficiently handling both single-ended and differential signals. With high resolution and sampling rates, it ensures accurate and reliable data for real-time power monitoring and data analysis. It is widely used in power evaluation, electrical equipment testing, and other fields.

The temperature acquisition card is optimized for high-precision acquisition of thermocouple signals, supporting various types of thermocouples and offering high-resolution temperature data acquisition. Its high sampling rate and stable performance meet the precise requirements of temperature monitoring systems. This card effectively provides temperature change trends in automated testing systems, supporting thermal management and equipment performance evaluation.

The two cards serve their respective roles in power consumption acquisition and temperature monitoring. When used together, they enable comprehensive performance analysis and monitoring, making them ideal for a wide range of industrial, scientific, and laboratory testing environments. The detailed parameters are as follows:

- Voltage Acquisition Channels: 16 single-ended / 8 differential

- Voltage / Power Resolution: 12 bit

- Maximum Voltage Sampling Rate: 500 KS/s

- Voltage Input Range: ±10 V

- External Clock Range: 0 – 500 kHz

- Temperature Acquisition Channels: 8 thermocouples + 1 CJC

- Temperature Resolution: 24 bit

- Maximum Temperature Sampling Rate: 256 S/s

- Supported Thermocouple Types: J, K, T, E, N, B, R, S

- Bus Type: PCIe / PCI, high-bandwidth backplane direct connection

- Size / Weight: 3U single-slot PXIe, approx. 0.5 kg per card

- Scanning Mode: Asynchronous cyclic scanning (voltage channels)

4.2 PXIe Controller Core Parameters

Doewe Technologies' PXIe controller is equipped with an Intel Core™ i7 processor, offering a boost frequency of up to 3.5GHz. It supports 16GB of memory (expandable up to 32GB) and a 512GB SSD (expandable up to 2TB), meeting the requirements for large-scale data processing. The controller features multiple USB ports, gigabit Ethernet interfaces, and a DisplayPort display interface, ensuring excellent connectivity and image output capabilities. With a PCI Express x16 bus, it supports up to 24GB of bandwidth, ensuring high-speed data transmission. Its compact 3U/dual-slot design is suitable for various testing systems, and its operating temperature range is from 0°C to +50°C, providing high reliability and making it ideal for high-performance data acquisition and analysis systems. The detailed parameters are as follows:

- CPU: Intel Core™ i7-6820EQ, 2.8GHz (Boost up to 3.5GHz)

- Memory: Default 16GB, expandable up to 32GB

- Storage: 512GB SSD (default configuration), expandable up to 2TB

- Ethernet Interface: 2 Gigabit Ethernet ports

- USB Interface: Front panel with 4 USB 3.0 ports, 2 USB 2.0 ports

- Display Interface: Supports DisplayPort interface, maximum resolution 3840×2160@60Hz, with adapters for other standard display interfaces

- Trigger Interface: Front panel with SMB trigger connector, supports external triggering or PXI bus signal triggering

- Indicator Lights: Power and hard disk status indicator lights

- Bus Type: PCI Express x16, internally supports up to 16GB bandwidth, externally supports up to 24GB bandwidth (automatically adapts to x8/x16 or x4/x4 modes)

- Size: 3U/dual-slot PXIe standard

- Weight: Approximately 0.8kg

- Operating Temperature Range: 0°C to +50°C

- Storage Temperature Range: -45°C to +85°C

- Relative Humidity Range: 5% to 95% (non-condensing)

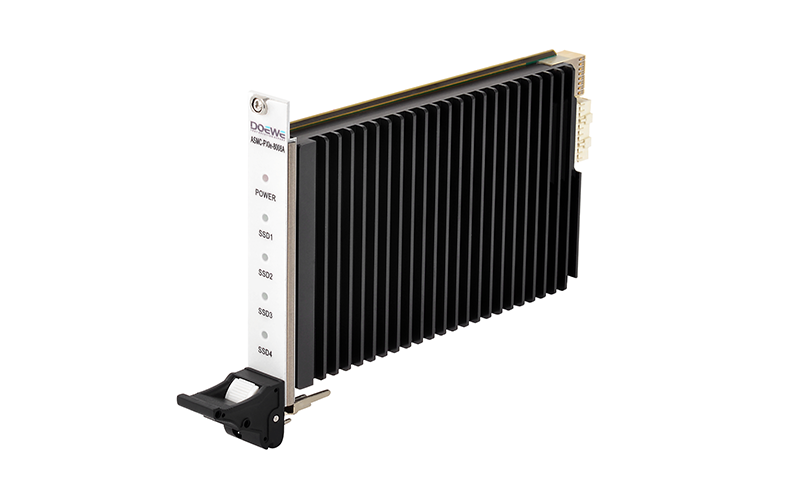

4.3 PXIe Storage Card Core Parameters

This PXIe storage card uses a PCIe x8 bus interface and provides an ultra-large storage capacity of up to 16TB, meeting the requirements for large-scale data storage. Its maximum read speed is 6.67GB/s, and the maximum write speed is 6.53GB/s, ensuring stable and efficient data storage support during high-speed data acquisition and processing. Designed to comply with the 3U single-slot PXIe standard, it weighs approximately 0.5kg, making it easy to integrate into various testing systems. The operating temperature range of this storage card is from 0°C to +50°C, with a storage temperature range of -45°C to +85°C, offering strong environmental adaptability for long-term stable operation. Its high reliability and excellent performance make it an ideal choice for data-intensive applications and high-performance computing systems. The detailed parameters are as follows:

- Capacity: Up to 16TB

- Interface Type: PCIe x8 bus

- Maximum Read Speed: 6.67GB/s

- Maximum Write Speed: 6.53GB/s

- Size: 3U single-slot PXIe standard

- Weight: Approximately 0.5kg

- Operating Temperature: 0°C to +50°C

- Storage Temperature: -45°C to +85°C

- Relative Humidity: 5% to 95% (non-condensing)

4.4 High and Low Temperature Alternating Test Chamber Core Parameters

- Chamber Dimensions: 800×600×850mm (Depth × Width × Height), Volume 408L

- Test Item Dimensions: Not provided

- External Dimensions (approx.): 1500×1150×1920mm (Depth × Width × Height)

- Temperature Range: -40°C to +150°C

- Temperature Fluctuation: ≤±0.5°C

- Temperature Uniformity: ≤±2°C

- Temperature Deviation: ≤±2°C

- Heating Rate: 2-3°C/min, average, no load

- Cooling Rate: 1°C to 1.2°C/min, average, no load

- Humidity Range: 10% to 98%

- Humidity Deviation: ≤±3%RH (>75%RH); ≤±5%RH (≤75%RH)

- Humidity Fluctuation: ≤±2%RH