1. Introduction

With the continuous evolution of Bluetooth technology, an increasing number of products are utilizing Bluetooth as a medium for information transmission. Its application scenarios are constantly expanding, encompassing consumer electronics, automotive electronics, smart home appliances, industrial, medical, and multiple other fields. Currently, there are tens of billions of Bluetooth devices on the market, and this number is expected to continue growing in the future. According to the requirements of the Bluetooth Special Interest Group (SIG), any Bluetooth device must pass Bluetooth protocol testing and certification before it can enter the market. Therefore, conducting RF conformance testing on Bluetooth devices during the R&D and production phases is crucial to ensure their wireless performance meets the requirements of the Bluetooth RF specifications.

2. Bluetooth Development History

During its development, Bluetooth has undergone several standard changes and technological updates. Bluetooth 1.1 was formally included in the IEEE 802.15.1 standard, but as an early technology, it suffered from issues like poor interference resistance and data leakage. After Bluetooth 2.0, EDR technology was added, increasing the transmission rate of Bluetooth devices. Bluetooth 3.0 significantly reduced power consumption and introduced the optional High Speed technology, achieving eight times the transmission rate of Bluetooth 2.0. Bluetooth 4.0 introduced three modes: Classic Bluetooth (BR), High-Speed Bluetooth (EDR), and Bluetooth Low Energy (BLE), greatly enhancing transmission technology, with the most important being the BLE low-power feature. Bluetooth 5.0 offered faster and longer-range transmission capabilities in low-energy mode. Bluetooth 5.2 enhanced the ATT protocol, LE power control, and signal synchronization, enabling faster, more stable connections with better interference resistance.

3. Test Solution

The test solution offered by Beijing Doewe Technologies Co., Ltd. supports Classic Bluetooth (BR), High-Speed Bluetooth (EDR), and Bluetooth Low Energy (BLE) technologies. It complies with Bluetooth protocol core specifications versions 1.1, 1.2, 2.0, 2.1, 3.0, 4.0, 4.1, 4.2, 5.0, 5.1, and 5.2 (continuously updated).

3.1 Test Case

Taking Bluetooth wristband RF conformance testing as an example, the specific test solution is as follows:

3.1.1 Single DUT Test Solution

Figure 1: Bluetooth Wristband RF Conformance Test Connection Diagram

The single DUT Bluetooth RF conformance test system primarily includes: BTE100 Bluetooth Comprehensive Tester, antenna or RF cable, control PC, and the Device Under Test (DUT).

The DUT establishes a connection with the tester either via an antenna over the air (OTA) or through an RF cable. The tester is connected to the control PC via a LAN cable. Start the tester and the DUT, confirm the connection status in the BTE Run test software, select the DUT version and test mode, check the required test items, run the test, and obtain the results.

3.1.2 Multi-DUT Test Solution

Figure 2: 1-to-4 Over-the-Air (OTA) Test Diagram

The multi-DUT Bluetooth RF conformance test system primarily includes: BTE100 Bluetooth Comprehensive Tester, antenna or RF cable, control PC, shielded box, and the DUTs.

Multiple DUTs are placed in corresponding positions on the tray within the shielded box. They establish connections with the tester either via antennas OTA or through RF cables. The tester is connected to the control PC via a LAN cable. Start the tester and the DUTs, confirm the connection status in the BTE Run test software, select the DUT versions and test mode, check the required test items, run the test, and obtain the results.

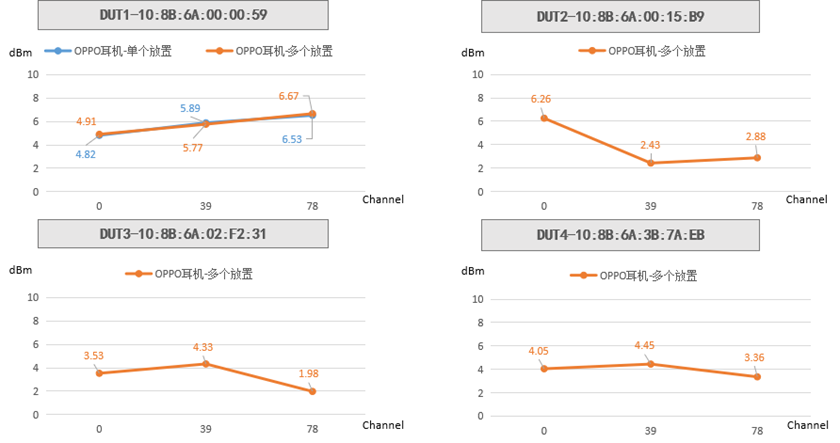

The BTE100 features industry-leading technology enabling OTA 1-to-4 testing. The test system can simultaneously conduct OTA tests on multiple terminals. The Bluetooth board supports multi-board testing (supporting simultaneous testing of up to four terminals, i.e., the 1-to-4 solution). It ensures that the data for the four DUTs is essentially consistent with individually measured data. Compared to the average output power of competing products in the industry: the deviation is <0.5 dB. This solution is suitable for large-scale mass production testing on production lines. It significantly improves industry testing efficiency, saves time costs, and provides great convenience for R&D testing.

Figure 3: BTE100 Average Output Power Comparison Chart

3.2 Test Items

3.3 Solution Advantages

● Fully compliant with RF conformance test standards.

● Compatible with Classic Bluetooth (BR/EDR) protocol testing and Bluetooth Low Energy (BLE 4.2/5.0/5.1/5.2) protocol testing.

● Enables rapid testing of various RF indicators such as power, frequency, modulation/demodulation, receiver sensitivity, and throughput.

● Possesses a complete Bluetooth protocol stack, supports Pairing Mode, no need to enter DUT mode – a powerful tool for competitor analysis.

● Supports full signaling testing for BLE, no need to enter DTM mode, friendly for products without USB interfaces.

● Supports CW calibration and testing, conducted or OTA testing.

● Features industry-leading technology enabling OTA 1-to-4 testing, significantly improving testing efficiency.

4. Introduction to Core Test Instrument

For Bluetooth RF conformance testing, the BTE100 Bluetooth Comprehensive Tester marketed by Beijing Doewe Technologies Co., Ltd. fully meets the requirements.

Figure 4: BTE100 Bluetooth Comprehensive Tester

The BTE100 Bluetooth Comprehensive Tester features a complete Bluetooth protocol stack. It is widely used in production, R&D, testing, and certification phases, and is also suitable for custom development based on Bluetooth protocol-level testing requirements. It supports different Bluetooth versions, offers very comprehensive testing functions, achieves OTA 1-to-4 testing, and performs better than other test systems currently available on the market.

Welcome to inquire and discuss. Inquiry Tel: +86 10-64327909.